Brief Introduction of Polyimide

Polyimide is a kind of macromolecule polymer containing cyclic imide group in molecular chain. (Polyimide, referred to as PI). Recently, the research, development and utilization of polyimide have been listed as one of the most promising engineering plastics in the 21st century.

polyimide

Brief Introduction of Polyimide

Polyimide is a kind of macromolecule polymer containing cyclic imide group in molecular chain. (Polyimide, referred to as PI). Recently, the research, development and utilization of polyimide have been listed as one of the most promising engineering plastics in the 21st century. Polyimide material has excellent high temperature resistance, low temperature resistance, high strength and high modulus, high creep resistance, high dimensional stability, low thermal expansion coefficient, high electrical insulation, low dielectric constant and loss, radiation resistance, corrosion resistance and other advantages. At the same time, it has the characteristics of low vacuum volatility, less volatile condensate and other space materials. It can be processed into polyimide film, high temperature resistant engineering plastics, composite materials. Matrix resins, heat-resistant adhesives, fibers and foams are widely used in many high-tech fields, such as aerospace, microelectronics, precision machinery and medical devices. [1,2,7]

polyimide

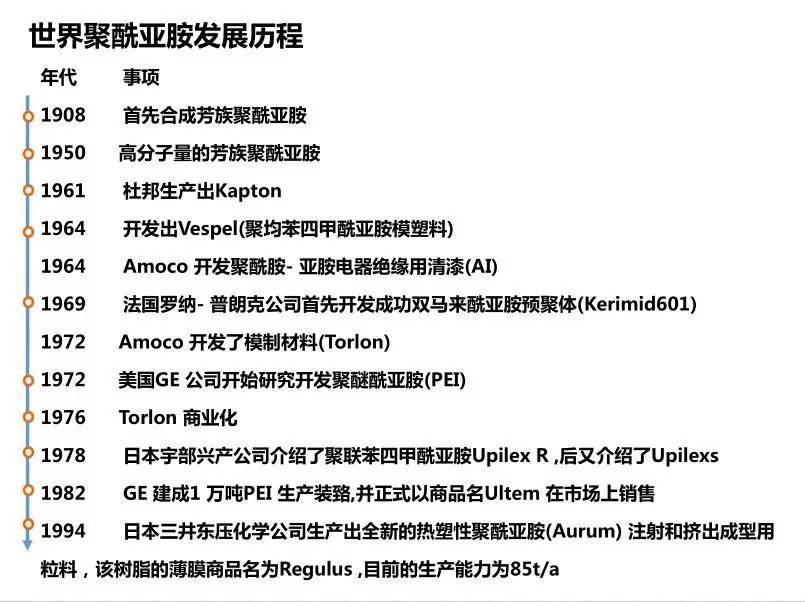

Development of Polyimide

Polyimide was first reported in 1908, but due to the knowledge level at that time, it did not receive enough attention. Polyimide was not mentioned in some patents in the 1940s until the 1920s when polymers were first recognized by the world. In the 1950s, polyimide, as a kind of polymer material, began to develop. With the development of the times and the increasing demand for high-performance materials, polyimide has become a research hotspot in recent years because of its excellent comprehensive properties. Its main development process is as follows:

Main Manufacturers of PI Films Abroad

Dupont(Dupont):Since 1950, DuPont Company of the United States began to study high temperature resistant polymers. In 1962, aromatic polyimides began to be trial-produced in Buffalo, named "H" film. In 1965, a large-scale production plant was established in Secklevine, Ohio, and registered as Kapton. There are three types of "Kapton" films: H-type, F-type and V-type. By 1980, more than 20 specifications of three types (7.5-125 um) were produced, with a width of 1500 mm. Through technical improvement, DuPont introduced three kinds of improved Kapton films in 1984, namely HN, FN and VN. The modified polyimide films have accounted for 85% of the total production of imide films.

Introduction of DuPont Polyimide Standard Products:

Product model | Characteristic | purpose |

Kapton® CR | Corona-resistant PI film | Insulation system |

| Kapton® FCR | Preventing Partial Discharge and Overheating | Large industrial automobiles, traction motors, generators |

Kapton® B | Black, even and opaque, | Heater, Antenna, LED Circuit, Application of Precision Laser Ablation |

Kapton® FN | PI Film Coated with FEP Perfluoroethylene Propylene Fluoride Polymer on One/Two Sides of Universal Kapton < HN | Oil Pipe and Heater Circuit、ResistanceThermal Sealable Plastic Bags、Diaphragm and Valve Set, Electrical Insulation Material for Automobile |

| Kapton® HN | The service temperature can range from - 269 to 400 C. | Universal type, which can be used in places where performance temperature is maintained within a wide range of requirements.。 |

| Kapton® HPP-ST | Excellent adsorptivity and dimensional stability | Electronic Parts, PCB Template, Screen Printing, Heat Insulation Pipe |

| Kapton® PST | Superior tensile strength, good elongation The difference between MD and TD attributes is minimal, and excellent dielectrics | Designed for pressure sensitive tape industry |

Kapton® MT+ | Excellent combination of thermal, electrical and mechanical properties | Applied in electronic and automotive fields, such as insulation pad, heater circuit, power supply, ceramic plate substitution |

Source Dupont official website

Dupont-Toray: In 1983, Dupont and Toray established Toyota Products Co., Ltd. in a semi-joint venture. Dupont provided technology and raw materials to specialize in the production of Kapton PI films. The film was put into production in September 1985 with a width of 1500 mm. In April 1999, DuPont announced its investment in Taiwan, China. In 1996, it built the first polyimide (PI) plant, Taiju Company, and became the main shareholder of the company, making Taiju the company that mainly produces PI film and flexible composite materials in Taiwan.

Umo Hitachi (ube): In the early 1980s, Japan Umo Hitachi Industrial Corporation developed a new type of linear polyimide, including UpilexR, UpilexS and UpilexC series films. The independent development model of UPilexR and PI film with capacity of 1 million square meters per year (80 tons per year) was put into production in 1983 and an additional model of UpilexS was added in 1985. Upilex has a maximum width of 1016 mm. There are three types of Upilex: R type, S type and C type. The thickness specifications range from 25 to 125 um (of which there are 7 specifications for R type and C type). Compared with Kapton, UpilexS has high heat resistance, good dimensional stability and low moisture absorption.

Japan's Yumo Hing PI Products Introduction:

product type | number | purpose |

PI membrane | UPILEX®-S(base grade) | Circuit Board Base Film, Cover Film, Reinforcement Plate, Flexible Display, Flexible Solar Cell Base Film, Electronic Device Film, Solid Curing System Carrier Film, Hot Pressure Isolation Film, Adhesive Film Base Material |

UPILEX®-RN(molding grade) | Embossed products, shielding materials, reflectors, insulation products, etc. | |

UPILEX®-VT(surface thermal adhesion grade) | Heat-resistant insulating film, metal mould protective coating, PCB substrate, multilayer substrate interlayer insulating film | |

PI powder | UIP-R,UIP-S | Polyimide Raw Materials, Fluorocarbon Resin Modification, Diamond Grinding Stone Adhesive |

PIcoating | UPIA® | High Temperature Resistant Coatings, Antirust Paint, Secondary Batteries, Electrode Adhesives, Coating Materials, Flexible Device Substrate, Touch Panel Substrate, TFT Base。 |

PICopper-clad laminate | Upisel®-N | FPC, TCP, MCM-L, COF, rigid-flex boards multilayer board, metal board, high frequency board, heat insulation board, IC card, automobile board and electromagnetic wave shielding material. |

PIBase resin | PETI-330, PETI-340M | High Temperature Jet Engine Assembly Aircraft Structural Components and Starting Vehicles Other High Temperature Resistant Components and Structures |

Kaneka, Japan: The first research on polyimide film in the laboratory began in 1980, and a new type of PI film called "Apical" was successfully developed. In 1984, Shiga, Japan established the first APICAL polyimide film production line, and began mass production in 1985. The product was mainly used in FPCS. Allied-Signal Sales Company was established in 1986; APICAL NPI model with superior dimensional stability was developed in 1988; Kaneka/Allied JV Company was established in 1989 in the United States (mainly for manufacturing and marketing); Allied-APICAL Company was established in the United States in 1990 and began to produce polyimide film in Texas; APICAL polyimide film obtained ISO9002 Certificate in 1993. APICAL NPI model won the Kinki Chemical Association Award; APICALAH model production thickness specifications in 1995 were 175, 200 and 225 microns; Kaneka High-Tech Materials (KHM) was established in 1997; KHM became a branch of Zhongyuan Texas Company in July 2006. "Apical" PI products are mainly used in FPCS (Flexible Printed Circuit Board), electronic materials, satellites, superconducting facilities, insulation coating materials and so on.

Mitsui Chemicals, Japan: Based on its own unique polymer design technology and reaction technology, high heat-resistant and transparent PI films have been developed. The glass transition temperature is over 260 C, and the light transmittance is over 88.0%. The product AURUM ("thermoplastic polyimide") can be used in precision machinery, industrial machinery, electrical and electronic products, automotive transport machinery, special wire sheaths, film fiber, composite materials.

Mitsubishi Gas MGC: At present, the only manufacturer in the world with the ability to produce transparent PI film in a real industrial way, meets the needs of electronic products with high heat resistance and transparency. The products are mainly used in soft display related products and optical components.

SKCKOLONPI, Korea: A joint venture between SKC and KOLON to integrate the polyimide film industry was established in June 2008. SKC started the research and development of polyimide film in 2001, and participated in the government's polyimide research and development project with KRICT in 2002; established the first PI production line in 2003 (0# test line); installed and commissioned the 0# production line of PI film in 2004, and succeeded in mass production, becoming the first enterprise to manufacture imide film in Korean history; completed the development of IN and IF model in 2005 (12.5). Establishment of 1 batch production line and successful sale of SKC imine film; completion of IS model development in 2006.

Polyimide

PI Manufacturers in Taiwan

Taiwan Taimide

Polyimide film products include: (source Taimide official website)

1. Taimide < TH, film thickness between 12.5 and 125 microns; 2. Taimide < TL, film thickness between 12.5 and 50 microns, can be applied to flexible printed circuit boards, protective films, enhanced plates, composite boards, flexible copper foil substrates, etc.

3. Taimide < TX, thickness 7.5 um, can be applied to thin high temperature insulation tape, thin pressure sensitive tape, soft and hard bonding plate.

4. Taimide < BK, black polyimide film, thickness of 10-75 micron, can be applied to high temperature opaque insulation tape, opaque enhancement plate, composite board, etc.

5. Taimide < OT, colorless polyimide film with thickness of 12.5-50 micron, can be applied to high temperature colorless protective film, soft display, soft electronics, etc.

6. Taimide < WB, white polyimide film with thickness of 12.5-25 micron, can be applied to soft printed circuit board, high temperature resistant white protective film, reinforcing film, LED lamp bar, bar code printing, etc.

Taiwanese Dasheng Technology: mainly produces high-functionality, full-size PI films. Dasheng Technology is the only manufacturer in Taiwan of China that can produce 12.5-225 micron full-size high-performance PI films. It is mainly used in semiconductor and photoelectric industries such as LED packaging, LED soft lamp. It is also one of the few black PI film manufacturers.

Polyimide

Domestic Mainland PI Manufacturers

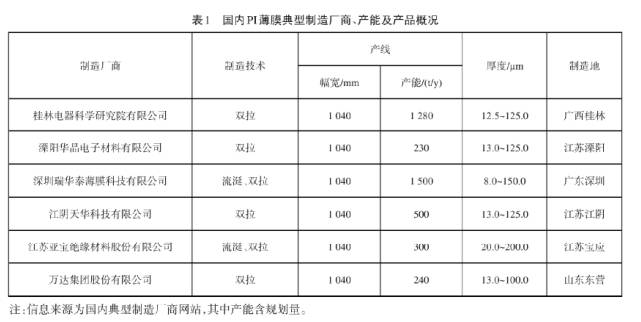

According to the application of different terminal electronic products, the thickness specifications of PI films can be divided into 7.5, 12.5, 24.0 and thick films. Handheld electronic products such as mobile phones and cameras use 12.5 or thinner PI films. General electronic products, automobiles, notebook computers and coatings use 25.0 micron thick PI films to repair. Thicker PI film was used for the plate.

The industrial profiles of several typical PI film manufacturers in China are as follows:

Guilin Electrical Research Institute Co., Ltd. Products include biaxially oriented polyimide film, black PI film, corona resistant PI film, etc.

Liyang Huajing Electronic Material Co., Ltd. is a professional manufacturer of biaxially oriented polyimide films. The PI base films cover six thickness specifications: 13, 25, 50, 75, 100 and 125 microns.

Jiangyin Tianhua Technology Co., Ltd. adopts the most advanced salivating biaxial stretching process to produce polyimide film (BOPI) in our country. It mainly produces FP series for flexible printed circuit board, FC series for copper film and T series for some special tape film and H series for electrical film. At present, the nominal thickness is 13 and 25 microns, and the monthly production is about 150,000 square meters.

Wanda Group Microelectronic Materials Co., Ltd. specializes in the production of biaxially oriented polyimide film (PI film), with world advanced production equipment, annual production capacity of 200 tons. The main production specifications are: 0.0125 mm, 0.025 mm, 0.05 mm, 0.075 mm, 0.08 mm and other specifications.

Shenzhen Ruihua Tai Film Technology Co., Ltd. cooperates with Institute of Chemistry, Chinese Academy of Sciences to develop high-performance PI film materials based on bi-directional stretching, colorless transparent and industrialized development of microporous membranes for high-tech industries such as flexible flat panel displays, automotive high-power fuel cells and organic thin film solar cells. Black PI film manufacturer.

Ningbo Jinshan electronic materials: polyimide products cover a wide range, including 1. common polyimide film 2. black polyimide film 3, antistatic black polyimide film 4, corona resistant polyimide film 5. mouldable polyimide film 6, thermal conductive polyimide film 7, white polyimide film 8, high strength and high film PI resin 9, aluminized PI film

Changchun Kawasaki: The annual production lines of 5000 and 2000 high performance thin films and conductive thin films were completed in 2012. They are used in OLED white light illumination, thin film solar cells, transparent films against electromagnetic radiation, radio frequency circuit boards, touch screens and other fields.

Tianjin Jiayi: The main products are functional corona-resistant PI films.

Jiangsu Yabao Insulating Material Co., Ltd. At present, the main products are polyimide films of various specifications and F46 polyimide composite films, of which 0.025-0.225mm thick polyimide series films have passed UL safety certification in the United States and SGS report in the European Union.

Changshu Zhongxin Aerospace Insulation Village Material Co., Ltd. The main products are PI film (polyimide salivating film), FEP film (FH, FHF polyimide-fluorine-46 composite film) and various specifications of silicone tape. Annual production of PI film 160 tons, FEP film more than 100 tons.

Polyimide

Recent Applications of Polyimide

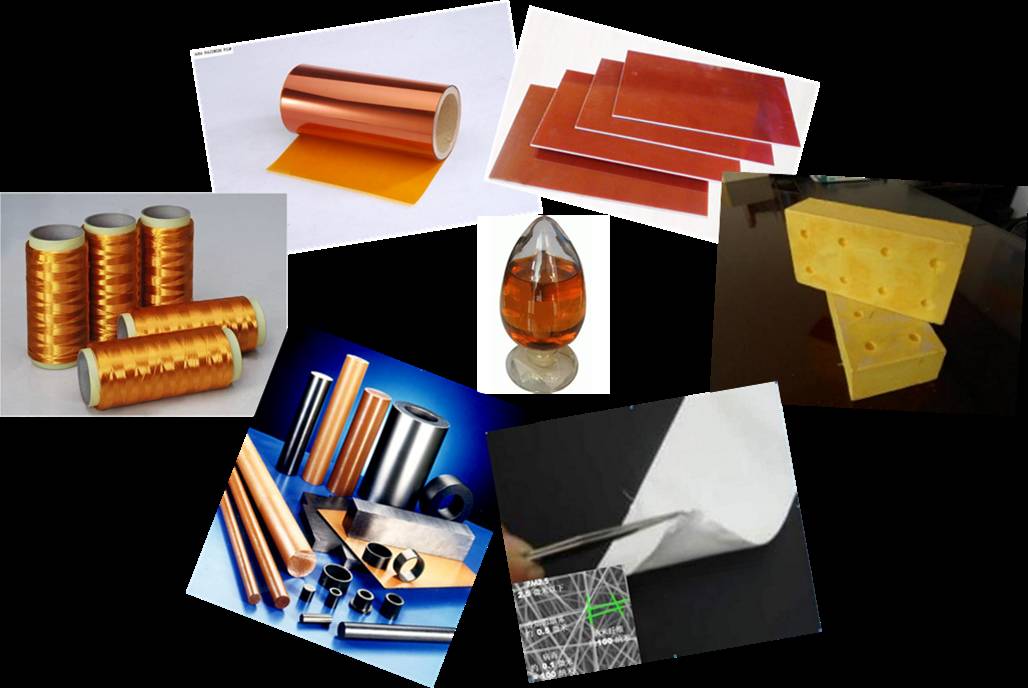

The main application forms of polyimide are films, composite materials, coatings, fibers, foam plastics, nanofibers and so on.

PI film is one of the earliest and most mature applications of polyimide materials.

1) Application of PI Film in High Speed Traffic

It can be used for high-speed motor insulation in high-speed train, PI insulation film of motor and so on. The reason why the fast-developing high-speed railway generator can operate safely and smoothly is that the insulation system of motor uses high-performance polyimide film insulation material.

2) Application of PI Film in New Energy Field

Because of its outstanding high temperature resistance and insulation performance, polyimide can be used in new power batteries, battery diaphragms for high-power electric vehicles, insulation of variable frequency motor for wind power generation and other new energy sources.

3) Application of PI thin films in space exploration

It can be used in space station solar panels, satellite multi-layer thermal blanket, solar sail surface, space panel heater and so on.

4) Application of PI Thin Film in Electronic Information

Because of its soft, dimensional stability and excellent dielectric properties, polyimide film can be used for flexible printed circuit boards, flexible IC packaging substrates and automatic welding of carrier tapes.

5) Colorless transparent PI film [1]

It is used in new generation flexible display, electronic paper, smart card, electronic tag, optical sensor, flexible solar panel, etc.

6) PI Advanced Composites

Excellent heat resistance makes it widely used in aeronautics, spacecraft and rocket structural components and engine parts.

7) PI coatings/coatings:

In February 2017, Dongfang Boiler Co., Ltd., Sichuan Polytechnic Institute and Zhongtiansheng New Material Technology Co., Ltd. of Zigong City will pioneer the application of polyimide coating material technology in the electric power industry through cooperative development, so as to prevent polyimide from corrosion at the cold end of air preheater. The development and application of equipment surface anti-corrosion, chimney inner surface anti-corrosion, desulfurization and electrostatic precipitation in low temperature environment broaden the thinking.

8) Application of PI Fiber

Polyimide fibers have excellent mechanical properties, high and low temperature resistance, self-extinguishing properties, radiation resistance, dielectric properties, corrosion resistance, biocompatibility and low density due to their special imide ring structure. They are the most excellent organic fibers with excellent comprehensive properties. However, due to the insolubility and insolubility of polyimide, it is very difficult to spin high strength and high modulus polyimide fibers. At present, only the Austrian Wingchuang Company has built a production line of polyimide fibers for high temperature filtration.

High temperature resistant PI fibers

It can be used in high temperature filter material, fire fighting clothes, insulating paper, battle clothes and space suits, etc.

High Performance PI Fiber

Because of its high-strength and high-modulus characteristics, it can be used in aerospace and military fields where material performance requirements are very high, such as engine shield, radar radome, body armor, protective nets, etc. It is also gradually popularized in civil use, and can be used in light-weight and high-strength bicycles, tire cord and so on. At present, an innovative team led by Professor Wu Dezhen of Beijing University of Chemical Technology and Chairman of Jiangsu Suno has developed and built the first production line of high strength and high modulus polyimide fibers with an annual output of 30 tons at home and abroad. The tensile strength of the PI fibers produced by the production line can reach 3.5 GPa. By controlling the molecular structure of PI, high strength and high modulus PI fibers satisfying different performance requirements are produced.

9) Other applications:

Engineering plastics: Thermosetting and thermoplastics, thermoplastics can be moulded or injection moulded or transfer moulded. Mainly used for self-lubrication, sealing, insulation and structural materials. Guangcheng polyimide material has been used in compressor rotor, piston ring and special pump seal and other mechanical components.

Foam Plastics: Used as High Temperature Insulation Material

Separation Membrane: Used for the separation of various gas pairs, such as hydrogen/nitrogen, nitrogen/oxygen, carbon dioxide/nitrogen or methane, to remove water from air hydrocarbon feed gas and alcohols. It can also be used as pervaporation membrane and ultrafiltration membrane. Because of the heat resistance and solvent resistance of polyimide, it is very important for the separation of organic gases and liquids.

Adhesive: Used as high temperature structural adhesive, high insulation filling material for electronic components.

Photoresist: Negative and positive adhesives with sub-micron resolution. It can be used in color filter film with pigments or dyes, which can greatly simplify the processing process.

Electro-optical materials: Used as optical switch materials for passive or active waveguide materials, fluorine-containing polyimides are transparent in the range of communication wavelength, and the stability of materials can be improved by using polyimides as chromophore matrix.